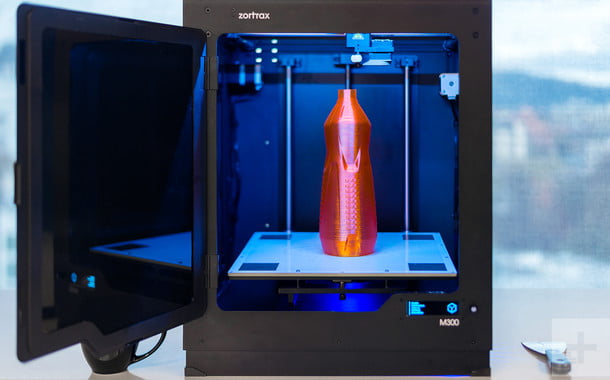

"The Zortrax M300 prints beautifully, but urgently needs a new build plate and some software updates."

-

Robust, attractive frame

-

Excellent printing performance

-

Large building envelope

-

Perforated building board makes it difficult to remove parts

-

Onboard and offboard software are limited

-

Bowden tube anchors can fail

-

Expensive

When it comes to 3D printing companies, Zortrax is not as well known as Makerbot or Ultimaker – but it has been making 3D printers for quite some time. In fact, the company's M200 printer (which was released back in 2012) is generally considered one of the best FDM printers you can buy.

For this reason, we were very excited when the company launched the new M300: a larger, worse version of its flagship machine. To find out how it stacks, we put the printer through its paces over the course of a month. That's how it went.

Excellent functions and specifications

The first thing you'll likely notice about the M300 is that it's huge. This isn't exactly a desktop printer, so you should definitely plan to allocate some space for it. With a weight of 110.2 pounds and an outer dimension of 18.6 inches x 19.2 inches x 26.1 inches, this thing is a big, beefy bastard of a printer. Fortunately, this also means that it has a fairly large build area – with a spacious 11.8 "x 11.8" x 11.8 "envelope.

Some other nice features you'll find on this device are: a heated bed (which increases grip and prevents pressure deformation), semi-automatic bed leveling, a small LCD screen for navigation and removable front / side panels.

The otherwise great foundation of the M300 is adversely affected by a variety of small design flaws.

The M300 also comes with something that we have never seen before and that scratched our heads in confusion. This "function" is a perforated building board – something that makes little sense for a machine that squirts out molten plastic to make items. We'll discuss why shortly.

Unfortunately, this seemed to be an ongoing issue for the printer. While it is clearly well made and has admirable features, the otherwise great foundation of the M300 is adversely affected by a variety of small design flaws and mysterious oversights.

Setup and config

Setting up the M300 is relatively simple and straightforward, but requires a bit of assembly and heavy lifting. Once you have released the printer from its packaging and attachments, you will need to attach the printer's build plate. Fortunately, this is not particularly difficult and only requires attaching a few wires to a clearly marked outlet.

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

You can then start the printer and start inserting the filament to the hot end. Zortrax's instructions on board will guide you through the device. The semi-automatic bed calibration of the printer is also fairly simple and guides you through the leveling process before you start printing.

Overall, the M300 is certainly not the easiest machine we've ever set up, but it's still pretty darn easy. As long as you are able to read and follow basic instructions, you shouldn't have any problems.

User interface / software

While the built-in controls on the M300 are easy to use and understand, there are some minor issues in the built-in software interface that make printing difficult. For example, when printing starts, you can no longer interact with the device. There is no pause / resume function and no possibility to adjust settings during operation or to cancel printing immediately. The only way to stop printing is to turn off the device – which is puzzling because these features are standard on most modern printers. Needless to say, the M300's unfinished software later led to some annoying usage problems.

Removing a finished print from the M300 is like pulling Excalibur out of the stone while trapped in a broom cupboard.

With the offboard software, the M300 works exclusively with the Z-Suite slicing program developed by Zortrax. The serial code from the back of our printer was required to download the program and was requested again during installation. While this is not the worst thing in the world, we found it to be over the top, superfluous and slightly annoying.

After putting the Z-Suite into operation, we were satisfied with the clear user interface, the easy-to-navigate design and the entertaining graphics – and were immediately disappointed with the simplified printing options. The program seems to be aimed at beginners and is therefore very easy to use, but unfortunately omits a number of "advanced" print adjustment options that are extremely important. For example, there is no clear way to switch off support structures, rafts or to optimize the filling settings. This is extremely frustrating and generally means that you will burn the filament faster.

Design / build quality

The design of the M300 takes up one page of the Z-Suite book, and by that we mean that it has a strong foundation and is clearly well made, but also has annoying disadvantages. Individually, these problems are not a big deal, but together they are enough to spoil an otherwise outstanding machine.

We start with the good things. The M300 has one of the most stable frames we have ever seen in a 3D printer. It is built like an air raid shelter and would probably print well in an 8.7 magnitude earthquake. It also has a clean, attractive look and comes with side panels that allow you to hide the mechanical guts from view.

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

But then there is the perforated building board. It is a double-edged sword because it keeps prints stable while printing, but it also makes them a great pain when printing is finished. To make matters worse, there is also no easy way to remove the print bed from the printer. So you have to pry the print out of the limited limits of the inner chamber of the printer, scrape it off and provide it with a spanner. In other words, removing a finished print from the M300 is like pulling Excalibur out of the stone while trapped in a broom cupboard.

Most of our prints were incredibly clean, detailed, and almost flawless.

And another thing: the perforations on the build platform effectively prevent you from printing without a raft (a few layers of support structure printed under the object to improve adhesion and prevent warpage). When you do this, the best scenario is that you have a series of plastic hubs at the end of your object. The worst scenario is that when you try to pull it off the build plate, your pressure won't easily release and crack (which has happened to us a few times).

Most frustrating, however, is that this perforated design is completely unnecessary. We believe that Zortrax contains the perforations to improve bed adhesion. The thing is, however, that the M300 already has a heated bed and automatically prints with rafts – both of which would probably have done the trick and reduced adhesion / warping problems. The perforations are redundant and cause more problems than they solve.

Unfortunately, the M300's problems don't end there. Another major design flaw was the printer's Bowden tube assembly. The Bowden tube, which is used to guide the filament to the print head, is attached to the rear of the printer using adhesive pads on the back of the plastic clips. The glue on these pads eventually failed during printing, causing the filament to detach from the spool and knot – which ultimately blocked the printer and ruined 13 hours of printing.

Trying to use the M300 for large-format, multi-hour prints is a risky business with no sensors to detect that filaments may run out or jam or even pause when this happens.

Printing performance

Despite the problems on the hardware side as well as on the software interface, both the included print (a strange bottle without a bottom) and our standard 3DBenchy test print have proven themselves remarkably well.

With a maximum print resolution of 90 microns and excellent dimensional accuracy, most of our prints were incredibly clean, detailed and almost error-free. We have one of the best benchy boats we have ever printed.

The M300 also copes with gaps and overhangs, as well as some of the best FDM printers we have ever seen, and praised virtually all of the prints it has completed. Unfortunately, due to hardware problems, we weren't able to give him many chances to prove ourselves, but we were very impressed with the print quality we saw in the pieces we finished.

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

When it comes to reliability, the M300 definitely needs some work. When a print is complete, that print will undoubtedly look good – but the machine doesn't always do the print jobs you give it. Until you have secured the Bowden tube and prevent it from loosening and getting your filament tangled, you should not entrust the M300 with large prints lasting several hours. Fortunately, however, this is the only real reliability issue. We have never experienced any faults or prints that have come off the bed.

Our opinion

The M300 is like a chubby house on a solid foundation. In its current form, it's not something you want to live in, but if the landlord had made a few minor touch-ups, it would be a great place to hang your hat.

In other words, the M300 has the potential to be an amazing machine, but its design flaws mentioned above hold it back. With an update of the software and firmware, this printer could possibly be among the best in its class. Medium print options, more control in the Z-Suite and a print bed without holes would take the M300 to the next level.

Is there a better alternative?

Given the M300's price of $ 2,990, there are dozens of alternatives that offer better performance and reliability.

For a bit more money, you can get a Formlabs Form 2 SLA printer – a device that is far superior to the M300 in terms of print quality and is generally considered one of the best 3D printers for consumers on the market. It's worth noting, however, that Form2's resin-based printing technology makes it somewhat more difficult (and sticky) to work with.

If the SLA print does not sound appealing and you prefer to use an FDM printer, we recommend the Ultimaker 2+. It offers better printing performance, a comparatively large build area and none of the annoying problems that plague the M300. For $ 2,999, you even get the Extended Edition, which has a larger footprint and allows you to build larger parts.

Another good choice would be the Lulzbot Taz 6, which doesn't look nearly as good as the M300, but is far more reliable, upgradeable, and optimized. If you are looking for a workhorse that can do work for work, the Taz 6 is the printer for you. It is also a few hundred dollars cheaper and offers an almost identical turnaround.

How long it will take?

The M300's robust construction and excellent build quality will likely keep this printer running for a long, long time. However, the software, software, and firmware of this printer are already out of date and need to be updated. When Zotrax releases an update that fixes some issues, this printer keeps ticking for years.

Should you buy it

At this point, no. With other options that offer more for your money, the M300 is not a printer that we can recommend – at least not at the moment. The large build volume, impressive print quality, and robust structure are tempting, but the myriad design flaws and limited control over printing parameters make it one of the most frustrating printers we've ever used. If these problems were fixed, the M300 would be a dream, but at the moment you should spend your money somewhere else.

Editor's recommendations