"Sparkmaker is definitely a fixer upper. In other words, you should steer clear unless you are ready to tinker with something."

-

Affordable

-

High print resolution

-

Compact and quiet

-

Favorable construction

-

Buggy software

-

Small build volume

-

Unreliable prints

When 3D printing was just beginning to become mainstream, the only printers available to consumers used a technique called filament deposition modeling (FDM). This is the type of 3D printing you've probably seen before: a printer passes a strand of plastic filament through a hot nozzle and carefully places the melted goose bumps layer by layer on a building board to create a 3D object.

This is by far the most popular and widely used style of 3D printer, but a technology known as stereolithography (SLA) has recently increased. SLA printers create objects by flashing light into a pool of photoreactive resin that hardens when UV light hits it. Because of the precision of this technique, SLA printers generally produce much better parts than FDM printers.

The only problem, however, is that this type of printer has been prohibitively expensive in recent years and therefore out of reach of the average consumer – but that is beginning to change.

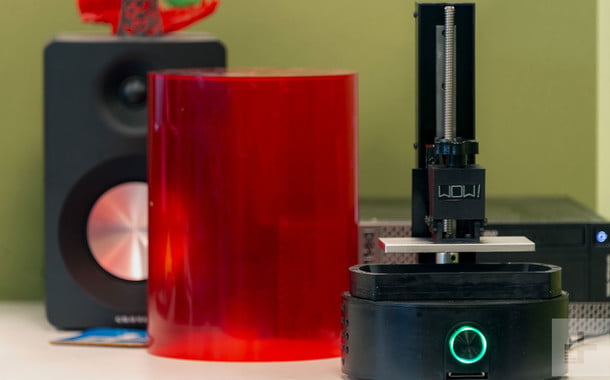

A typical example? The $ 300 Sparkmaker Printer. The Sparkmaker was born from a Kickstarter project that started in early 2017. It is one of the first SLA / DLP printers to pass the $ 500 mark. So we got one to see how it stands out from the competition.

Excellent functions and specifications

The first thing you'll notice about the Sparkmaker is its small size and light weight. At just 6 pounds and 6 x 11 inches in size (it's a cylinder), it's definitely one of the smallest printers on the market. While it won't be hard to find a place for the little guy, it has a downside.

By lifting the orange UV protection hood, the tiny 4 x 2.2 x 5 inch construction envelope of the printer becomes visible. This is certainly not the smallest footprint we have ever seen, but you shouldn't expect large prints to be made on this device. On the other hand, Sparkmaker has a removable resin container that makes changing materials a breeze.

The Sparkmaker owes its low price to its relatively simple printing technology. Instead of using a laser like Formlabs' printers, Sparkmaker uses a UV-backed LCD screen to project an image into a resin container, which solidifies it – a process called DLP. Despite some minor disadvantages, this printing method offers the Sparkmaker a maximum resolution of ten micrometers. For those of you who want to score at home, this is ten times more detailed than an average FDM printer and about 1.5 times more detailed than the $ 3,500 Ultimaker 3 – arguably the best consumer-level FDM machine currently on the market.

Setup and configuration

In contrast to FDM printers, the Sparkmaker has only one moving component and does not require assembly. Therefore, the setup is extremely simple. After connecting, all you need to do is pour some resin into the tank and make sure the build plate is level. Once you've done this, you're ready to print.

You will definitely not find another SLA / DLP printer that matches Sparkmaker's $ 300 price tag.

Then there is the software. Like many printers today, Sparkmaker has its own cutting program that can be downloaded free of charge from the manufacturer's website. It's called Sparkstudio, and it's one of the most intuitive and accessible we've ever used compared to most other proprietary slicing programs.

Unfortunately, we encountered some bugs that affected the experience (more on that later), but overall this printer is a breeze.

Design and build quality

Sparkmaker is inexpensive for a reason. Most of the body is made of plastic and the parts feel a bit thin and cheap. The makers definitely made some cuts during manufacturing, and that shows it.

The biggest misstep in machine design is a tiny component called a "lead screw". It is a small threaded tube that moves the building board smoothly along the Z axis – or at least it should. Due to the faulty design of this component, the up and down movement of the build plate is susceptible to periodic jerks and jumps that cause problems during the printing process.

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

However, there is a fairly simple workaround for this problem. After some advice from the Sparkmaker Facebook group, we used another 3D printer to print a new lead screw. This simple exchange drastically improved the success rate and overall consistency of the printer. If you want to buy this printer, you should definitely plan to replace this screw.

Apart from the faulty lead screw, the rest of the printer works pretty well. The removable resin tank is easy to remove and replace, and the build plate itself is secured with a single button screw, simplifying the process of removing the finished print from the printer.

Another bonus is that the Sparkmaker is generally incredibly easy to disassemble and edit – which is good as it definitely requires some crafting.

User interface and software

Sparkmaker's integrated user interface is practically non-existent and consists of a single push button. Unlike other printers that use this design, however, that's all Sparkmaker has to offer. There is no associated screen that you can use to navigate, so the device lacks a number of helpful features. This includes: stopping printing, adjusting device settings without connecting to a computer, and selecting specific files on your SD card for printing. The latter is particularly annoying as you are then forced to either remove or rename old files. Sparkmaker only recognizes cut files with the name "Print.wow". It's not the worst problem you could ever have, but it's definitely one of those annoying quirks that make working with the machine a problem.

Due to software errors and hardware errors, this machine has an above-average failure rate.

Fortunately, the associated desktop software Sparkstudio partially compensates for these problems with an excellent user interface that is both feature-rich and easy to navigate. In other words, it's simple and accessible to beginners, but it also offers extensive customization options so that advanced and advanced users are not left out to dry.

To our great delight, Sparkstudio also offers a tool that is generally only available for high-end slicing software: customizable supports that you can place or remove manually. If this isn't your bag, the software will still include an automatic support placement that you can change posthumously. It is really neat and we want more slicing programs that offer this kind of functionality.

Despite all the good things, Sparkstudio suffers from a few debilitating mistakes that affect the experience. First, there is a scaling error that randomly adjusts the length, width, height, or size of the objects you cut into slices – without any advice or warnings. During our testing, this resulted in a 3DBenchy tug that was twice what it should have been, and a skull that was about a tenth of the height we originally set for it. This error, combined with an inconsistency in what caused our prints to fail, prompted us to use a completely different slicer program. In the end, we used SLAcer: a custom slicer that fixes Sparkstudio's mistakes above, but also doesn't offer many of its best features – including the custom support placement feature.

All in all, Sparkstudio has enormous potential, but is held back by a few obvious shortcomings. It is possible that WOW! These problems may be fixed in the future, but the software is frustratingly buggy in its current state. Until these problems are resolved, use a more reliable but less feature-rich slicing program.

Printing performance

Despite the problems with consistency and splitting errors, the Sparkmaker prints surprisingly well – (when it's done). With its maximum resolution on the Z axis of 10 micrometers, this small device can print amazing details and super fine geometry. Some of our test prints show a slight voxel formation (a consequence of the printer's DLP printing technology). However, the effect is only noticeable when you search for it.

Bill Roberson / Digital Trends

Bill Roberson / Digital Trends

Overall, the virtues of the Sparkmaker outweigh its shortcomings in terms of print quality. It's definitely not on the same level as the Formlabs Form 2, for example, but let's not forget that it's a $ 300 printer we're talking about here. It is a tenth of the price of a top-of-the-range machine, but offers only slightly lower quality. It is quite impressive.

However, print quality is only part of the equation. Consistency and reliability are the other part of it, and unfortunately that's where Sparkmaker comes up short. Due to the software errors and hardware errors mentioned above, this machine has an above-average failure rate.

Despite all its shortcomings and shortcomings, we liked this printer.

Even after we fixed the lead screw problem and switched to a less faulty cutting program, we still experienced a high number of botched prints. According to our count, you have a 50/50 chance that the print will not adhere properly to the build plate. You can fix this problem by printing on the underside of your object with an improvised "raft". However, this raft cannot be removed and there is still a good chance that it will not stick anyway.

All in all, we would say that the Sparkmaker produces impressively detailed prints in about 30 percent of the cases. The other 70 percent make something that resembles postmodern glitch art. However, we will continue to work on and update this article as we figure out how to get better and more consistent prints.

Our opinion

Despite all its shortcomings and shortcomings, we liked this printer. It's compact, quiet, and the only printer we've ever tested that didn't drive everyone in the office with its vapors or noise. It is also very affordable, relatively easy to update, and occasionally produces outstanding prints.

Still, Sparkmaker is definitely not a good printer for beginners. In its current state, it is too flawed, too flawed, and too unreliable to recommend it to anyone just breaking into the 3D printing scene. However, if you're enjoying a little challenge and aren't afraid to get your hands dirty, the Sparkmaker is a fixer upper that could be worth your time.

Is there a better alternative?

You will definitely not find another SLA / DLP printer that matches Sparkmaker's $ 300 price tag. However, there are some competitors that you can buy for around $ 500 – like the Wanhao Duplicator 7 with a slightly larger build volume and a built-in menu navigation screen.

If you haven't chosen an SLA / DLP printer, there are a handful of good FDM printers on the market that you can put your paws on for around $ 300. For price-conscious buyers, we recommend Monoprice's $ 160 mini-delta printer. It may not match the Sparkmaker's print resolution, but it has a larger footprint and is far more reliable.

For those who don't mind spending a little more, you can also buy a Monoprice Maker Select Plus for $ 400. It's a little more expensive, but for that extra $ 100, you get a much larger footprint and a full range of high-end features.

How long it will take?

With its cheap parts and plastic case, the sparkmaker's lifespan is probably definitely dependent on how you treat it. Without regular maintenance, we would be willing to bet that things will fail after a year or two. However, if you keep it up to date and keep it well oiled, it will likely continue to tick after the age of 5 – assuming WOW! continues to release firmware updates and bug fixes.

On the positive side, there are numerous instructions for corrections and upgrades in the Sparkmaker community. We found endless support from the Facebook community when we encountered problems from both other users and the developers themselves.

Should you buy it

If you are new to 3D printing and want something that is easy to use, don't buy this printer. We guarantee that you will pull your hair out. However, if you're ready to get messy and do some DIY upgrades, Sparkmaker may be just the thing for you. With a little tinkering, you can definitely make this machine shine.

Editor's recommendations