Anycubic Photon 3D printer

"The Photon is one of the most detailed 3D printers you can get for $ 500 – but it's not perfect."

-

Extremely detailed prints

-

Touchscreen interface

-

Affordable price

-

No peeling mechanism

-

Small building area

Until recently, consumer-level stereolithography printers were essentially the unicorns of the 3D printing world. For years, there were few of them sold to consumers, and they were usually far too expensive for most 3D printing enthusiasts to afford.

Fortunately, that is starting to change. Over the past year, resin-based printers have entered the consumer market with increasing frequency – and this includes some extremely affordable options.

A typical example? The Anycubic Photon, one of the first SLA / DLP printers to hit the market at under $ 500. But can a cheap printer really be compared to industry giants like Ultimaker, Lulzbot and Formlabs? We took a spin to find out.

The Anycubic Photon was awarded the prize for the best products of the year. Make sure you check all other choices for the best 2018 products.

Excellent functions and specifications

There are a few things that make this printer stand out from the rest of the pack. It is primarily a DLP printer. This means that instead of spraying plastic filaments through a hot nozzle to create objects, UV light is radiated into a container with photoreactive resin to harden each layer. It is a fundamentally different machine than the Makerbots and Ultimakers in the world.

Dan Baker / Digital Trends

Second, it's tiny. In contrast to most consumer 3D printers, the Photon is about the size of two assembled shoe boxes and can therefore fit comfortably on your desktop. Unfortunately, this tiny space requirement also means that the printer has a correspondingly small construction area, so that you cannot print anything larger than 115 x 65 x 155 millimeters (4.5 x 2.5 x 6.1 inches) with this device.

It is far more detailed than even the highest quality FDM printers we have ever tested.

Fortunately, the photon offsets its tiny footprint with some incredible resolution / accuracy statistics. It can print layers less than 10 microns thick, making it far more detailed than even the highest quality FDM printers we've ever tested.

To top it off, the Photon is also equipped with a 2.8-inch touchscreen interface, which makes it much easier to adjust settings and start printing.

Setup and configuration

Setting up an SLA / DLP printer differs significantly from setting up an FDM printer. The good news is that this is easier with the photon too.

The printer is almost fully assembled, so preparing it for the first print is a breeze. There are essentially two steps: install and level the build plate, and then attach the resin container.

Dan Baker / Digital Trends

Dan Baker / Digital Trends

Unfortunately, the process of leveling the building board is in no way automated, but it is still relatively easy to carry out. To ensure that you set the starting point of the Z axis to the correct height, Anycubic asks you to place a piece of printer paper on the LCD screen and then lower the build plate until you feel resistance as you move the paper. It's not the most polished system, but it works and can be completed in just a few minutes.

Once you have completed the leveling process, all you have to do is install the resin container and fill it with the supplied resin. All you have to do is loosen and tighten a pair of button screws, so you don't even need tools to do it.

Design and build quality

Don't be fooled by the fact that this printer only costs $ 500. It's amazingly well built for a printer that's so budget friendly. The building board and the resin tub are made of machined aluminum, for example, while the machine frame is made of stamped sheet metal. Nothing about it feels cheap.

The printer lacks many of the sophisticated design elements that are common in high-end machines.

However, the design is fairly simple. Aside from the touchscreen interface, the printer lacks many of the sophisticated design elements that are common in high-end machines. There is no automatic resin filler to begin with. So when your goose bumps run out, you have to stop the pressure and add more yourself. The photon also has no peeling or wiping mechanism, which increases the likelihood of printing errors.

It is also worth noting that this computer is designed to use a DLP process instead of a real SLA. This means that the printer does not flash and move a laser spot into the resin to keep track of the shape of each layer, but uses an LCD screen to cure an entire layer at a time. This leads to slight (but remarkable) differences in print quality, which we will discuss later.

Dan Baker / Digital Trends

Dan Baker / Digital Trends

All in all, this printer is very well built, but it lacks a bit of design – at least from a technical and performance perspective. From the appearance alone, it's almost impossible to say that the photon only costs $ 500. However, if you examine some of the technical elements closely, you can see where Anycubic cuts corners. Still, this is a lot of printers for the price.

User interface and software

The integrated user interface of the Photon is as simple and straightforward as possible. The menu directory is extremely simple, so you can hardly get lost or confused. In addition, everything is touchscreen, so navigation between the menus is very intuitive. If you can use a smartphone, you can use this printer.

Anycubic's proprietary slicing program, Photon Slicer, is also fairly simple – if not a bit primitive and functional. It's not very pretty to look at and feels a bit like a CAD program from 1997, but the advantage is that it's also pretty minimalistic. There are not many options in which you can get lost, which makes it very easy and accessible for beginners. Even without previous experience with the program, we managed to start it and prepare our first 3D model within a few minutes.

Printing performance

The photon has gotten a lot of hype in the past few months and after testing it for a few weeks, we are here to tell you that the hype is absolutely justified. This printer beats far beyond its weight class.

When we first printed it, we skipped the usual 3D benchmark benchmark and threw the photon directly into the deep end with a ridiculously detailed "Bearded Yell" statue. This print eats FDM printers for breakfast and usually has all kinds of aberrations, over-extrusion artifacts and significant loss of detail. We were excited to see if this small SLA printer could do better.

Dan Baker / Digital Trends

Dan Baker / Digital Trends

To our great joy, the photon made the model print look like a cake. There were some places where printing errors occurred, but the remaining 95 percent of the model was practically error-free. Fine details – such as the wrinkles on his forehead, individual hairs in his eyebrows and the shallow depressions in his molars – were all reproduced with astonishing accuracy. The surface quality was so good that it was almost impossible to distinguish one layer from the next. In some cases, the people we showed it to in the office didn't notice that the model was 3D printed.

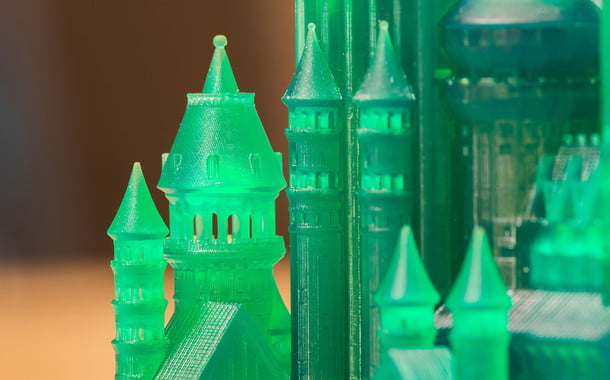

Our second test model (a very detailed lock) came out even better. Without a magnifying glass, we couldn't even see individual layers. Tiny elements like the battlements and battlements of the castle (which were so small that they justifiably couldn't be reproduced on an FDM printer) came out perfectly. The only other machine we've tested that delivers such incredible details is the Form 2, which costs $ 3,200.

This printer offers an incredible amount of bang for your buck when it comes to resolution and surface finish.

However, there were some minor problems. In our first two test prints, certain sections looked crushed as if someone had flattened them with a hot iron or hit them with a belt sander. These errors were caused by incomplete peeling – when the resin solidifies after the impact of UV light, but adheres more firmly to the bottom of the resin container than to the printed part, so the printer does not completely peel off to the next level.

Since the photon has no peel mechanism (some printers tip one end of the resin container so that the part gradually peels off from left to right instead of pulling straight up and peeling all parts at the same time), it is more prone to these types of errors. Despite the fact that the photon does not detach carefully, these errors have occurred to a very limited extent.

Dan Baker / Digital Trends

The other thing to note is that this DLP printer is also prone to voxelization due to its fact. Simply put, this is basically the 3D version of the pixelation. The UV light of this device is emitted from a pixel-based LCD screen, so that smooth curves cannot be generated at the microscopic level. Imagine trying to build a ball out of Legos. It is only on a really small scale.

Fortunately, in the case of the photon, this voxelization is so slight that you don't really notice it until you look for it. It's like watching movies on a huge TV. If you really approach, you can see the pixels, but practically nonexistent at normal range.

Our opinion

The Photon is without a doubt one of the best printers you can get for $ 500.

It's definitely not on a par with high-end printers like the Formlabs Form 2 when it comes to functionality and reliability, but in terms of pure print quality, it's just a few steps. If you print the same object on both machines and place it side by side, most people cannot tell the difference. That is damn impressive.

Is there a better alternative?

If you're looking for the most detailed, high-resolution prints for the least amount of money, look no further. This printer offers an incredible amount of bang for your buck when it comes to resolution and surface finish.

However, it is also worth noting that resin printers are not for everyone. Resin is sticky, messy, and a pain in the ass to clean up. You must soak finished parts in isopropyl alcohol to remove uncured resin and wear nitrile gloves to avoid direct contact. In other words, SLA printers are relatively maintenance-intensive. So if you are unwilling to post-process or plan to print in large quantities, we recommend sticking with FDM.

The photon is also not the best choice if you need to print large or even medium-sized objects. We recommend spending your money on an FDM printer like the Monoprice Maker Select Plus, which has a much larger envelope, but still costs less than $ 500.

How long it will take?

For the most part, there are not very many components on this machine that are likely to wear out – apart from the non-stick FEP plates on the bottom of the resin container, which you need to replace regularly anyway. The photon doesn't have many moving parts. As long as you keep the threaded rod oiled and maintain the resin pan carefully, it will likely take years.

Should you buy it

Hell yes you should. There are many ways to spend $ 500 and this is one of the best we can think of.

Editor's recommendations