MatterHackers Pulse XE NylonX Advanced Materials 3D printer package

"If you need to print with exotic, high-performance materials, this is the right printer."

-

Excellent out-of-box performance

-

Wide material capacities

-

Durable, well-designed components

-

Attractive, modern design

-

State-of-the-art functions

-

Requires a dedicated computer to reach its full potential

-

Lack of ventilation system

-

Not the fastest

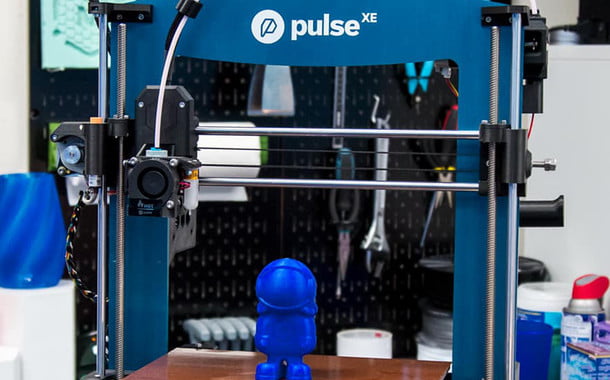

Printing with high-performance materials can be difficult. Sure, there are options on the market, but most come in the form of retrofitting aftermarket components to a printer in one way or another, at least in the mid-range consumer market. Enter the MatterHackers Pulse XE, the highest end of the MatterHackers Pulse line of 3D printers, and one of the few devices designed exclusively to instantly print some of the hardest materials on the market.

The pulse line is an interesting linchpin of its creators. MatterHackers has long been known as a reseller of a wide variety of 3D printers and materials that can be used with them. Thanks to this, MatterHackers has been effectively gathering information about what members of the 3D printing community expect from their printers for years and showing what types of pulses are available. The Pulse range is available in three options with multiple combinations of even more specialized hardware and a love letter to your market. Resolve dozens of common complaints with out-of-the-box hardware and include many of the most common aftermarket upgrades as standard components. In conjunction with MatterControl (MatterHackers control software), each pulse is an attractive product in itself.

STANDOUT FUNCTIONS AND SPECIFICATIONS

The outstanding selling point of the Pulse XE is its versatility, but also its user friendliness should not be underestimated. With a build volume of 250 x 220 x 215 mm (10 x 9 x 8.5 inches), the Pulse finds a good balance while maintaining a manageable space requirement with a respectable capacity.

In addition, the leveling routine via the connected BLTouch sensor ensures a reliable, easy-to-calibrate printer. The functions of MatterControl when a host device is connected to the printer make it incredibly easy to use. An optional magnetic removable build plate (included with this test model) makes removing the print incredibly easy.

James Lynch / Digital Trends

James Lynch / Digital Trends

Finally there is Olsson Ruby nozzle on hotend. The Pulse XE can hardly be called "high performance" when using a standard brass die for extrusion. The name of the Olsson Ruby nozzle doesn't just sound cool. At the top of this otherwise normal-looking 3D printer nozzle is a small ruby with an even smaller hole on the bottom that serves as an opening. The hardness of the ruby gives the nozzle an exceptional lifespan and enables it to withstand even the most abrasive filaments with ease. While other nozzle options exist that achieve similar goals, they are typically made entirely of hardened materials such as steel. The ruby achieves the same goal with a laboratory-made gem that is held in the head of the nozzle. Admittedly, this is the brightest way to get things done.

The Pulse XE was manufactured using some of the highest quality parts in the consumer for prosumer markets

Another unique feature of the Pulse line is that, unlike most printers on the market, MatterHackers printers are specifically designed for their MatterControl control software, as they work mostly independently and connect to a computer that serves as a backup option. Connecting a dedicated computer to the Pulse increases its capabilities through several functions that are otherwise only found in the upper market segment. From the ability to self-calibrate with up to 100 individual data points, to a greater degree of control over movement during printing, to the resumption of 3D printing that was interrupted in the event of a power failure or other power failure, MatterControl increases the flexibility of the Massive machine (as long as the semi-finished print is still on the bed when the power supply is restored). This doesn't mean that the Pulse can't work on its own in the same way as other printers, just that adding a dedicated controller turns a Matterhackers Pulse from a good all-round performer into a cutting-edge piece of personal manufacturing equipment.

BUILD QUALITY AND RELIABILITY

The quality of the Pulse XE should not be underestimated. With a frame made from a hybrid of specially machined aluminum, anodized extrusions and precise 3D printed components (undoubtedly made with other pulse printers), this printer was built for a long service life. The damping mounts attached to each of the motors offer noise reduction, and care and attention has obviously been put into the overall design. The underlying build quality is one thing, but a lot can go wrong on a 3D printer with good bones. So what about the other components? In this area, MatterHackers definitely used the best that they could find.

James Lynch / Digital Trends

James Lynch / Digital Trends

As an example, MatterHackers decided to use E3Ds v6, a precision-made hot end from one of the most respected brands in 3D printing. To push the plastic itself, the ultra-high-performance extruder from BondTech was selected to ensure additional performance. The Ultimachines RAMBo Mini-Motherboard (with Panucatt's Azteeg x5 GT as an even more powerful upgrade) forms the brain of the device and the excellent VIKI 2 control panel at the front.

In short, the Pulse XE has been manufactured using some of the best consumer end parts for prosumer markets and also uses many parts that are normally added to printers as aftermarket upgrades as standard. All of this results in a precision-made printer with a legendarily reliable extrusion mechanism, a long-life motherboard (just like Lulzbots Taz 6 and Mini, and I would say every motherboard that NASA trusts me will trust) with an easy-to-read, informative display the front of the device. In the month that I had the Pulse, he easily mastered every challenge I faced him and has printed almost continuously since leaving the box.

PERFORMANCE

Could the Pulse XE have disadvantages with all of these great features? Unfortunately yes. While the Pulse works incredibly reliably and immediately has remarkable versatility, the biggest disadvantage of the XE and the Pulse line in general is the underlying design. The Pulse XE is a 3D printer with a side bed or bed spinner, ie the print bed moves from side to side in one direction to move the model to be printed. This is an incredibly easy to construct, maintain, and repair design (since this configuration allows easy access to the axle and its parts), but has the obvious disadvantage that moving the bed can cause reliability problems if it moves too quickly (Due to the dynamics of the bed in the fight against changes in direction). . This can manifest itself in the fact that in extreme cases the entire pressure shifts from side to side to small, wavy lines over the pressure at lower speeds. Momentum is not a friend of a bed sling. This means that the Pulse XE prints at an average speed that should be enough for most, but fades compared to the speeds of some other models.

James Lynch / Digital Trends

James Lynch / Digital Trends

How good it prints, the Pulse XE works flawlessly right away. I have nothing to report about any scatter marks or stains, the layers are smooth and the corners are absolutely within the tolerances that you would expect. While it is worth noting that print quality for most 3D printers in the FDM or FFF category (i.e. they use a hot nozzle to extrude plastic filaments) may need to be roughly the same over time, modification and careful optimization the Pulse XE doesn't work whatever to produce excellent prints. With a thin layer of glue on the build plate and a short automatic calibration process, I was able to simply select "print" from the MatterControl user interface and leave, knowing that I would return to a finished model. The adhesive may be a sticking point for some, but is easy to apply and required to print the materials for which the XE was developed, such as. B. nylon (which has the ability to permanently bond to most reusable construction areas and thus permanently ruin them). A plate that does not require glue and is intended for use with other materials is available as an additional option from MatterHackers.

So if I am not talking about speed and not necessarily print quality, what am I talking about when I call the XE a "high performance" DD printer? In a word, materials. The components of the Pulse XE are designed to reach and withstand elevated temperatures, push plastic with greater force, and withstand the risk of damage from some of the more exotic materials. Some of these components are significantly more expensive than the standard, which explains the high cost of this machine, but the advantages are significant in terms of versatility. Thanks to these hardened components, the XE has access to materials such as nylon and polycarbonate, as well as materials with hard fibers or particles to increase strength, such as carbon or glass fibers.

Access to these materials opens up whole worlds to a print shop owner. Glass-infused nylon is widely used to manufacture power tool housings, drone frames, and low-power electronics heatsinks, while polycarbonate can be used for such diverse things as high-strength electronics housings, greenhouse walls, and any application that values high impact strength. Another advantage of the hardened nozzle, however, is a material that few newbies would consider a risky material for a printer, namely anything that glows in the dark. With its hardened nozzle, the Pulse XE can withstand the heavy load of hard particles, which give the objects glowing in the dark their clear shine, whereby the nozzle of a standard printer wears out as soon as the first layers of the material are in place. From surprisingly challenging to previously impossible, the MatterHackers Pulse XE seems to print with almost any plastic that can be turned into a string.

SAFETY

James Lynch / Digital Trends

James Lynch / Digital Trends

All of this goes well with an often overlooked disadvantage of working with such materials. Safety. I have used nylon extensively in my pulse testing over the past month, and during that time I had to feel quite comfortable in a ventilator because of the dangers of using such materials. For example, nylon releases some chemicals when it melts, but one of the most notable must be hydrogen cyanide. Yes, the cyanide. While my mask filters out a good amount of these toxic materials, it is certainly not a long-term solution. Proper ventilation through my skylights and exposure limitation also help, but an option for a filtered housing for the Pulse would work well for the future. Until then, use should be limited to a room where such materials are adequately ventilated and not in locations where the user can be continuously exposed to the materials during the printing process.

Our opinion

Overall, my time with the Pulse XE was phenomenal. From my fourteen printers, it quickly became a favorite, and the use was largely a blast. I can't imagine a task I couldn't do, and the latest version of MatterControl has proven to be an incredibly powerful control system. I would recommend it to anyone who wants to work with some of the wilder materials, and to those who are simply looking for a highly reliable printer, the cheaper standard Pulse is also a good choice.

Is there a better alternative?

While the desktop FDM printing market definitely has a lot of competition, the Pulse line stands out across the board. The basic Pulse model goes from head to toe with the original Prusa i3 MK3 / S, but offers the advantages of many other customization options and a shorter lead time.

In the meantime, the Pulse XE can be seen as a competitor to the Lulzbot Taz line and other real performance printers. In this case, the Lulzbot has an advantage in terms of build volume, but the ready-to-use ability of the Pulse XE to print with some of the most powerful materials on the market without modifications or additional components, magnetic beds, and slightly lower costs means that it is attractive Option remains.

How long it will take?

One of the biggest advantages of open source 3D printers like this is that their future lifespan is more or less unlimited. Both motherboards used in the Pulse run commonly used, widely used firmware systems that use a common protocol that has been standard in the 3D printing community for years. One particular advantage of the Pulse line is that it relies on MatterControl. Further updates to more advanced features are likely to be in preparation, and support for the product will be available in the coming years.

Should you buy it

Would you like to work with the best without fuss? If so, absolutely! Otherwise yes! This thing is awesome!

Editor's recommendations